Page 192 - CTB_Engilsh_Web_Version1

P. 192

Panipat Refinery, Technology with Ecology at Heart

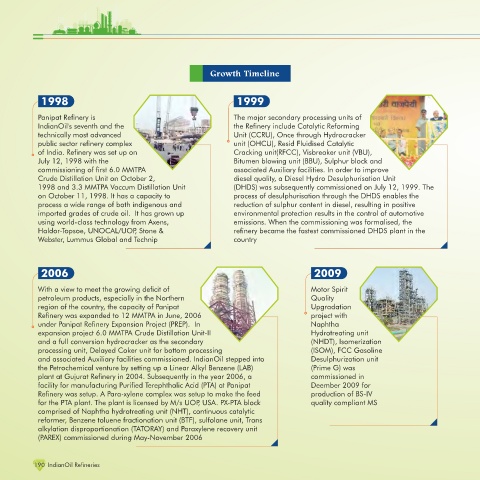

Growth Timeline 2010 2013

Þ The Naphtha Cracker Complex which is one of Butadiene

the largest of its kind in India comprising extraction unit

1998 1999 Naphtha Cracker Unit (NCU), NCU associated (BDEU) was

units, High Density Polyethylene (HDPE) Unit, Swing commissioned in

Panipat Renery is The major secondary processing units of (LLDPE/HDPE) Unit, Mono Ethylene Glycol (MEG) October 13 for

IndianOil's seventh and the the Renery include Catalytic Reforming

technically most advanced Unit (CCRU), Once through Hydrocracker Plant, Polypropylene (PP) line 1& Line 2 Units and Utilities extracting 1,3-Butadiene

including Captive Power Plant was commissioned between from cracked C4s. 1, 3

public sector renery complex unit (OHCU), Resid Fluidised Catalytic

of India. Renery was set up on Cracking unit(RFCC), Visbreaker unit (VBU), March 2010 to May 2010. The world-class Panipat Naphtha Cracker Butadiene is used for

July 12, 1998 with the Bitumen blowing unit (BBU), Sulphur block and was built at a cost of INR 14, 439 crore. The project is a cornerstone for production of Styrene Butadiene

rubber by neighboring M/s ISRPL.

IndianOil's entry into petrochemicals and forms a new business line for

commissioning of rst 6.0 MMTPA associated Auxiliary facilities. In order to improve

Crude Distillation Unit on October 2, diesel quality, a Diesel Hydro Desulphurisation Unit growth Butadiene is also sold to domestic

1998 and 3.3 MMTPA Vaccum Distillation Unit (DHDS) was subsequently commissioned on July 12, 1999. The Þ Further, to meet the potential demand renery capacity again augmented customers

on October 11, 1998. It has a capacity to process of desulphurisation through the DHDS enables the to 15.0 MMTPA in December, 2010

process a wide range of both indigenous and reduction of sulphur content in diesel, resulting in positive

imported grades of crude oil. It has grown up environmental protection results in the control of automotive

using world-class technology from Axens, emissions. When the commissioning was formalised, the

Haldor-Topsoe, UNOCAL/UOP, Stone & renery became the fastest commissioned DHDS plant in the

Webster, Lummus Global and Technip country 2014 2017

Butene-1 Unit was commissioned Sale of surplus Butene-1 was

in May 2014. Butene-1 is started

2006 2009 produced in the unit by

dimerization of ethylene. After

With a view to meet the growing decit of Motor Spirit commission of Butene-1 unit, import

petroleum products, especially in the Northern Quality was stopped

region of the country, the capacity of Panipat Upgradation

Renery was expanded to 12 MMTPA in June, 2006 project with

under Panipat Renery Expansion Project (PREP). In Naphtha

expansion project 6.0 MMTPA Crude Distillation Unit-II Hydrotreating unit

and a full conversion hydrocracker as the secondary (NHDT), Isomerization

processing unit, Delayed Coker unit for bottom processing (ISOM), FCC Gasoline 2018 2019

and associated Auxiliary facilities commissioned. IndianOil stepped into Desulphurization unit

the Petrochemical venture by setting up a Linear Alkyl Benzene (LAB) (Prime G) was Naphtha Cracker Unit (NCU) PNC has achieved highest ever

plant at Gujurat Renery in 2004. Subsequently in the year 2006, a commissioned in Expansion project was approved Naphtha processing (3027 TMT)

facility for manufacturing Puried Terephthalic Acid (PTA) at Panipat Deember 2009 for by Board in August. The project and highest ever polymers

Renery was setup. A Para-xylene complex was setup to make the feed production of BS-IV includes NCU Ethylene capacity production (1357 TMT)

for the PTA plant. The plant is licensed by M/s UOP, USA. PX-PTA block quality compliant MS enhancement from 857 kTA to 970 kTA

comprised of Naphtha hydrotreating unit (NHT), continuous catalytic by integration of Panipat renery off

reformer, Benzene toluene fractionation unit (BTF), sulfolane unit, Trans gasses from FCCU & DCU. The project

alkylation disproportionation (TATORAY) and Paraxylene recovery unit includes Ethylene Recovery Unit (ERU), NCU Expansion,

(PAREX) commissioned during May-November 2006 BEU Expansion and MEG Expansion

190 IndianOil Reneries IndianOil Reneries 191