Page 135 - CTB_Engilsh_Web_Version1

P. 135

Bongaigaon R e f inery , T echnology with Ecology a t Heart

Bongaigaon Refinery, Technology with Ecology at Heart

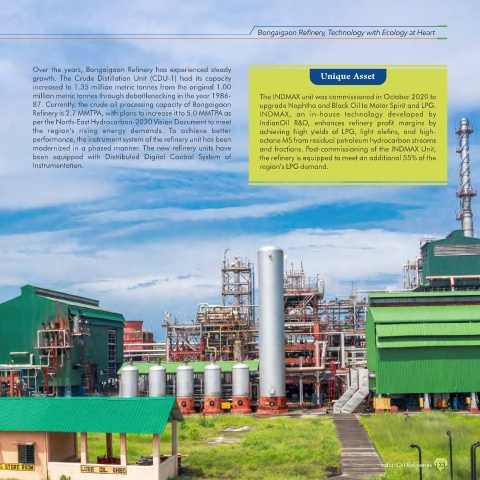

Giant Strides & Refinery Today Over the years, Bongaigaon Renery has experienced steady

growth. The Crude Distillation Unit (CDU-1) had its capacity Unique Asset

Big Steps, Bigger Impact

increased to 1.35 million metric tonnes from the original 1.00

million metric tonnes through debottlenecking in the year 1986- The INDMAX unit was commissioned in October 2020 to

Bongaigaon Renery was established with an initial investment of INR 460 crore. Its main goals were to 87. Currently, the crude oil processing capacity of Bongaigaon upgrade Naphtha and Black Oil to Motor Spirit and LPG.

rene Assam Crude Oil and manufacture petrochemicals as downstream products. Initially, Oil India Ltd Renery is 2.7 MMTPA, with plans to increase it to 5.0 MMTPA as INDMAX, an in-house technology developed by

and Oil & Natural Gas Corporation (ONGC) supplied crude oil to the renery from the oil elds in upper per the North-East Hydrocarbon-2030 Vision Document to meet IndianOil R&D, enhances renery prot margins by

Assam through pipelines. The crude tanks, which received the crude oil, were commissioned in 1979. The the region's rising energy demands. To achieve better achieving high yields of LPG, light olens, and high-

Captive Power Plant was commissioned on January 14, 1979. The primary unit was the Crude Distillation performance, the instrument system of the renery unit has been octane MS from residual petroleum hydrocarbon streams

Unit, which began operating in February 1979 with an annual capacity to process 1.0 million metric modernized in a phased manner. The new renery units have and fractions. Post-commissioning of the INDMAX Unit,

tonnes. Subsequent commissioning included the Kerosene Treating Unit (KTU), the Delayed Coking Unit been equipped with Distributed Digital Control System of the renery is equipped to meet an additional 55% of the

(DCU), and the Coke Calcination Unit (CCU), as well as the petrochemicals complex. Instrumentation. region’s LPG demand.

Bongaigaon Renery seen with a woman engineer on duty

IndianOil Reneries 133

132 IndianOil Reneries IndianOil Reneries 133

132 IndianOil Reneries