Page 58 - CTB_Engilsh_Web_Version1

P. 58

Guwahati Refinery, Technology with Ecology at Heart

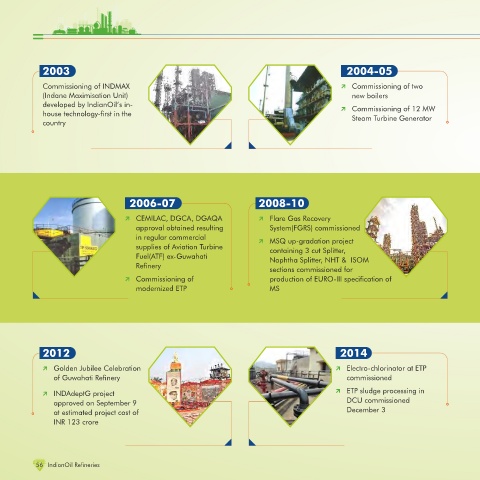

2003 2004-05

2015-16

Commissioning of INDMAX Þ Commissioning of two

(Indane Maximisation Unit) new boilers

developed by IndianOil’s in- Þ Installation of 150 KW Solar PV systems on top of hospital

Þ Commissioning of 12 MW

house technology-rst in the Steam Turbine Generator Þ First batch of BS-IV HSD produced successfully on April 30

country

Þ Successful production of BS-IV compatible PCK established

2017

2006-07 2008-10

Þ Received the 1st rake of imported crude on January 27 and processed the rst batch of

Þ CEMILAC, DGCA, DGAQA Þ Flare Gas Recovery imported crude on January 28

approval obtained resulting System(FGRS) commissioned

in regular commercial Þ Continuous production of BS-IV MS started

Þ MSQ up-gradation project

supplies of Aviation Turbine Þ The INDAdeptG Unit commissioned on January 31 based on the technology of

containing 3 cut Splitter,

Fuel(ATF) ex-Guwahati desulphurization of INDMAX Heavy Gasoline developed by IndianOil (R&D)

Naphtha Splitter, NHT & ISOM

Renery Þ New Tank Truck loading facility commissioned on March 2

sections commissioned for

Þ Commissioning of production of EURO-III specication of Þ First rake of Reformate received directly from Paradip Renery (with RON 102 & 7 ppm S)

modernized ETP MS in October

2012 2014 2018

Þ Golden Jubilee Celebration Þ Electro-chlorinator at ETP Þ Production of BS-VI MS and HSD, investment approval accorded on August 28 at an

of Guwahati Renery commissioned estimated cost of INR 557.44 crore

Þ INDAdeptG project Þ ETP sludge processing in Þ Revised Stage-1 approval for Semi-Regenerative Catalytic Reforming Unit (CRU) Project of

DCU commissioned 90 TMTPA capacity accorded on August 11

approved on September 9

at estimated project cost of December 3 Þ The rst rake of low Sulphur ATF received via Tank Wagon (TW) Ex Haldia Renery on April

INR 123 crore 2

56 IndianOil Reneries IndianOil Reneries 57