Page 106 - CTB_Engilsh_Web_Version1

P. 106

Gujarat Refinery, Technology with Ecology at Heart

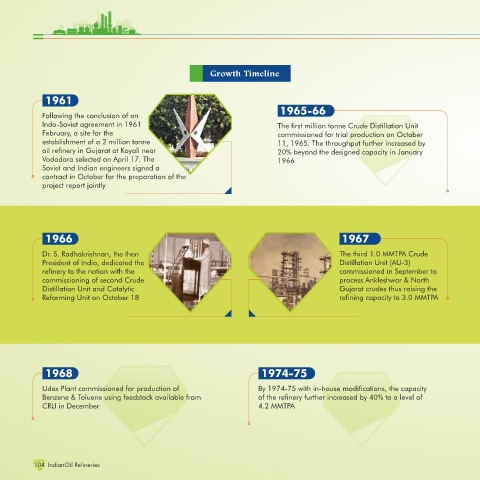

Growth Timeline 1978-79 1982

Secondary processing Þ To recover high value products from the residue, the

facilities, consisting of a secondary processing facilities consisting of Fluidized

1961 Fluidized Catalytic Catalytic Cracking Unit (FCCU) of 1.0 MMTPA capacity

1965-66 Cracking Unit (FCCU) with a along with a Feed Preparation Unit (FPU-1) of 1.7

Following the conclusion of an

Indo-Soviet agreement in 1961 The rst million tonne Crude Distillation Unit capacity of 1.0 MMTPA, along MMTPA capacities, were commissioned in December

February, a site for the commissioned for trial production on October with a Feed Preparation Unit Þ Pilot Distillation Facilities (PDF) for the production of N-

establishment of a 2 million tonne 11, 1965. The throughput further increased by (FPU-1) with a capacity of 1.7 heptane & Light Aluminum Rolling Oils (LARO) set up

oil renery in Gujarat at Koyali near 20% beyond the designed capacity in January MMTPA, commissioned in December. By

Vadodara selected on April 17. The 1966 1980-81 this unit started processing Bombay High

Soviet and Indian engineers signed a Crude in addition to imported crudes. It was for the

contract in October for the preparation of the rst time in Indian petroleum industry that Indian

engineers independently handled such a big project

project report jointly

1993-94 1999

1966 1967

To enable the absorption of increased Þ India's rst Diesel Hydrodesulfurization Unit (DHDS), commissioned

Dr. S. Radhakrishnan, the then The third 1.0 MMTPA Crude indigenous crude, the crude processing in June. Additionally, the MTBE Unit commissioned in September to

President of India, dedicated the Distillation Unit (AU-3) capacity of the renery was further increased eliminate Lead in Motor Spirit (MS)

renery to the nation with the commissioned in September to to 9.5 MMTPA. In 1993-94, Gujarat Renery

commissioning of second Crude process Ankleshwar & North commissioned the country’s rst Þ Conceptualized and commissioned South - East Asia’s largest

centralized Efuent Treatment Plant in June

Distillation Unit and Catalytic Gujarat crudes thus raising the Hydrocracker Unit with a capacity of 1.2

Reforming Unit on October 18 rening capacity to 3.0 MMTPA MMTPA, designed to convert the heavier ends Þ Atmospheric Distillation Unit-5 commissioned in September.

of crude oil into high-value, superior products Capacity augmented to 13.7 MMTPA making it the largest PSU

renery of the country

2004 2010-11

1968 1974-75 World's largest Single Train The Residue Upgradation

Linear Alkyl Benzene (LAB) Plant Project and MS/HSD quality

Udex Plant commissioned for production of By 1974-75 with in-house modications, the capacity set up marking IndianOil's big- improvement project

Benzene & Toluene using feedstock available from of the renery further increased by 40% to a level of

ticket entry into the Petrochemicals commissioned increasing the

CRU in December 4.2 MMTPA

eld. The project completed in distillate yield by 8 to 10%

record 23 months

104 IndianOil Reneries IndianOil Reneries 105